| Sign In | Join Free | My ledscreensign.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ledscreensign.com |

|

Brand Name : GDS

Model Number : MG-1280

Certification : CE

Place of Origin : CHINA

MOQ : 1 PIECE

Price : CONTACT US

Payment Terms : T/T

Supply Ability : 30pcs/Mon

Delivery Time : 10 working days

Packaging Details : plywood case

Name : Potting Machine

Application : Led Lights Assembly

Function : automatically potting AB glue

Working Power : AC220V 50HZ/2000W(stirring,vacuuming, heating not included)

Working Pressure : 0.5-0.8Mpa

Working Temperature : 0-40℃

Glue Potting Machine delivering precise glue application for enhanced battery durability and optimized of potting materials

Machine description

Glue Potting Machine represents a pivotal advancement in battery manufacturing, offering precise glue application to significantly enhance battery durability and optimize potting material usage. This technology addresses critical challenges in battery production, where inconsistent glue dispensing can lead to premature failure or reduced performance. By delivering exact amounts of adhesive with high accuracy, the machine ensures uniform coverage, which is essential for protecting battery components from environmental stressors like moisture and temperature fluctuations. Such precision minimizes material waste, lowering production costs while maintaining rigorous quality standards.

The machine's key advantages include its ability to adapt to diverse battery designs, from small-scale consumer electronics to large industrial systems, ensuring versatility across applications. Its automated processes reduce human error, boosting efficiency and reliability in high-volume production environments. Moreover, by optimizing potting material application, it enhances battery longevity by preventing internal corrosion and mechanical wear, which are common causes of degradation.

This leads to improved safety and performance, as well-formed potting layers provide better insulation and structural integrity.In summary, Glue Potting Machine stands out for its transformative impact on battery manufacturing. By combining precision, efficiency, and material optimization, it not only elevates product durability but also supports sustainable practices through reduced waste. As industries increasingly demand reliable energy storage solutions, this technology emerges as a cornerstone for innovation, driving progress in sectors reliant on advanced battery systems.

Machine Feature

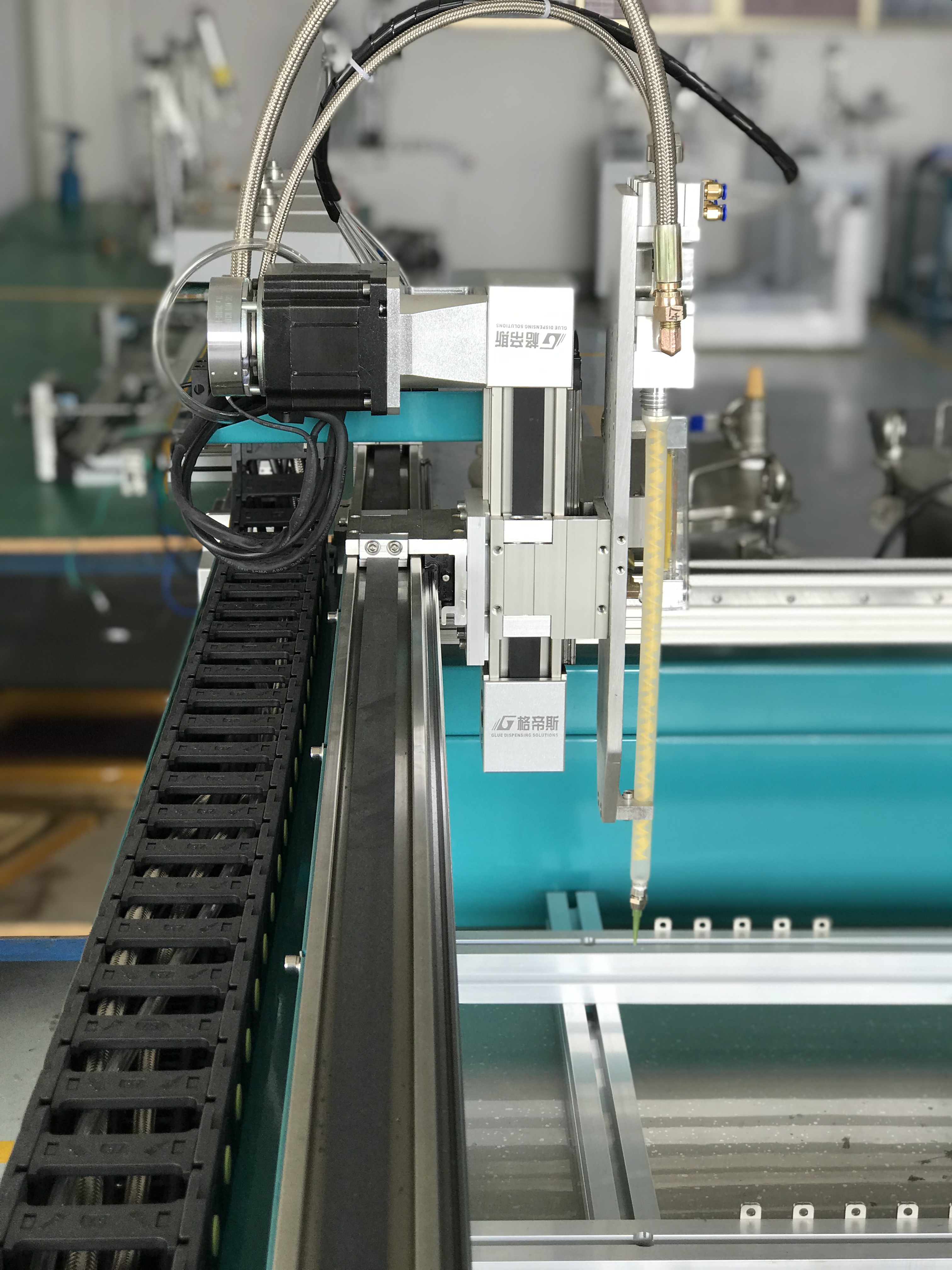

3 axis mechanical hands employ high precision linear movement module to ensure accurate movement and high repeat accuracy;

Touch screen operation plus handhold teaching programming case, easy to learn and operate;

According to the feature of products and production capacity requirement, fixture and glue delivery head can be customized.

Technical Parameters

| Model | MG-1280 |

| Working Range | 1200*800*100mm(X*Y*Z) |

| Moving Speed | 0~500mm/sec |

| Repeat Accuracy | ±0.02mm |

| Mixing Proportion | 100:100~100:10(1:1~10:1) |

| Metering Method | Precise Gear Pump or Rotary Plunger Pump |

| Mixing Method | Static Mixing or Dynamic Mixing(based on glue nature) |

| Mixing Accuracy | ±1% |

| Glue Extrusion Accuracy | ±1% |

| Glue Container Capacity | 30L 304 Stainless Barrel |

| Glue Viscosity | Max≤20000CPS |

| Glue Additive Proportion | MAX≤100(Glue):100(Additive)(1:1) |

| Glue Additive Size | Max≤400tsp |

| Control Mode | PLC+Handhold Teaching Programming Case+Touch Screen |

| Programming | Teaching Programming |

| Program Capacity | At least 100 unit, 4000 points/unit |

| Transmission Method | Steeping Motor+Synchronous Belt+Linear Guide-way |

| Working Pressure | 0.5-0.8Mpa |

| Working Power | AC220V 50HZ/2000W(stirring,vacuuming, heating not included) |

| Working Temperature | 0-40℃ |

| Working Humidity | 20-90% no condensation |

| Dimension | 1680x1200x1600 mm(WxDxH) |

| Weight | About 350KG |

| Optional Functions | Glue container stirring, pre-heating, vacuum de-foaming, automatic cleaning |

Suitable Glue: two component glue, such as organic silicone, epoxy, PU, acrylate etc.

Applications:Small size products with small volume of glue, such as LED display, wall washer light, line light, Ads module, nixie tube, mutual inductor, transformer, power module, photo-voltaic module, automobile head light, daytime running light, negative-ion generator, crystal photo frame etc.

|

|

Glue Potting Machine delivering precise glue application for enhanced battery durability and optimized of potting materials Images |